Back to School – Retail Sales & Inventory Reporting

By Jim Lewis, CEO Improved Retail Options LLC

I just lately experienced the honor of lecturing at my alma mater, the University of Florida. We talked about the fundamental principles of retail analytics, the instruments and roles of retail and wholesale stock planners. We talked about how products conclusions are manufactured to ideally make magic on the product sales ground. But the magic does not constantly occur.

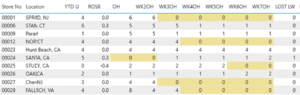

A university student requested what leads to a retail store to have empty shelves. Which is a total lecture inside alone. We talked about some of the factors- what can be managed and what can’t. They know what they read- that the pandemic induced havoc on the offer chain. Though that is authentic, there are numerous other causes, specifically now that the offer chain is easing. We centered on learning the mechanics of how out of shares result in dropped sales. One of the reports I showed the inventory of an item by retailer by 7 days, highlighting when it was out of stock. Pupils swiftly did the math to figure out how a great deal income was getting still left on the table.

Keep track of inventory by sku by 7 days by retail store to uncover outs and missing prospect.

Predicting Out of Shares

While there are some shops whose philosophy is that they’d fairly be out of stock than mark down an product, the huge greater part really don’t want to be out of inventory. Avoiding inventory outs requires a lot of moving sections to sync harmoniously. There ought to be a consistent move of stock coming from the wholesale facet with peaks and lulls taken into consideration. The allocation process depends pretty a lot on the sophistication of the retailer. Some car replenishment methods just stick to a bare minimum amount, some incorporate charge of sale to that, but most aren’t good more than enough to prioritize shops and merchandise that are out the most. And lots of really do not incorporate back again missing gross sales, which signifies the whole basis for the forecast does not replicate the genuine potential. Then there is the sheer quantity of sku’s- millions of sku-retail store mixtures to handle.

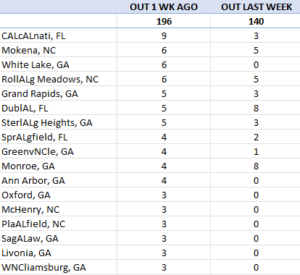

Maintain track of the suppliers or goods that are persistently out of inventory.

VMI

The finest technique for remaining in stock is VMI (Seller Managed Inventory) where the retailer employ’s their supplier’s sources to forecast and be certain stores keep in stock. It mainly indicates those sku’s will have a lot more focus on them than non-vendor managed items. This target enables the provider laser aim on shops and sku’s that are most probable to go out of inventory, and beef them up.

Scenarios

Even with the finest of intentions, there may perhaps not be more than enough stock or open up to acquire to allocate in the most productive method. Which is why documenting eventualities is significant. If you only have so many sources- which merchants or products receives fed to start with? What gets prioritized? Or does each keep get a more compact total? These could improve relying on the predicament, but we suggest building a “play book” so there’s a plan in spot.

Details Science

It actually is not mind science. We have an abundance of reports and units that continually review which goods and retailers are bought out- so that stock can be prioritized to resolve the difficulty. Centered on a combination of knowledge points- wholesale inventory stream, historic shop and merchandise inventory outs, seasonality, promotions, and many others., we use a couple straightforward algorithms to do the do the job. It does require highly effective computing ability to sift through thousands and thousands or billions of documents of data, so it is not for the faint at heart.

I normally take pleasure in speaking to college students. At its heart, ERS was established on instruction- educating producers to assume and act like stores. It has evolved into significantly extra around the last 20 a long time, but instructing remains a core concentration of our business.

For a lot more information, make contact with us.